Nuclear facilities

PRORYV PILOT AND DEMONSTRATION ENERGY COMPLEX (PDEC)

Seversk, Tomsk Region

CONCERN TITAN-2 is participating in the construction of the PRORYV Pilot and Demonstration Energy Complex as the General Contractor.

The Proryv Project is being implemented by ROSATOM on the premises of the Siberian Chemical Plant. The goal of the project is to create a closed nuclear fuel cycle technology. The pilot and demonstration complex will have a module to produce mixed-oxide fuel, a BREST-300 power unit, and an irradiated fuel recycling module.

Specialists of the Standalone Subdivision PRORYV are working on the site of Proryv PDEC. In 2022, CONCERN TITAN-2 welcomed student construction brigades of the All-Russian Students Construction Project.

KURSK NPP-2

Kurchatov, Kursk Region

The Standalone Subdivision of JSC CONCERN TITAN-2 is working at the construction site of two new power units with standard optimized computerized pressurised water (VVER-TOI) reactors. Specialists of the subdivision are engaged in the construction of facilities of the turbine islands and the evaporative cooling tower of Power Unit 2. Construction equipment of TITAN-2 Holding is also being used on the site.

The new power units of Kursk NPP are being built as replacement power for the operating power units with RBMK-1000 reactors. The gross installed capacity of the two NPP power units under construction will be 2,510 MW. Once built and put in operation, each power unit of Kursk NPP-2 will function in the normal operation mode for 60 years, generating power and supplying consumer heat.

Photo: Kursk NPP

Construction of a replacement Leningrad NPP (Leningrad NPP-2)

Sosnovy Bor, Leningrad region

Leningrad NPP-2 is the first Russian nuclear power plant belonging to the new 3+ generation with enhanced technical and economic performance. The new power units of Leningrad NPP-2 were built under the AES-2006 Project, which meets the requirements of the Russian environmental legislation, regulatory documents, and recommendations of the International Atomic Energy Agency (IAEA). The project fully meets the radiation safety criteria.

The company’s specialists performed the complete range of construction, mechanical installation and electrical installation works. The company's subsidiaries performed all preparatory works, including the excavation of pits for the main facilities of Power Units 1 and 2, and the bulk of in-situ concrete and civil works.

Power Units 1 and 2 of Leningrad NPP-2 were delivered in 2020. On 14 July 2022, a contract for the construction of Power Units 3 and 4 of LNPP-2 with VVER-1200 pressurised water reactors was signed, with JSC CONCERN TITAN-2 as the General Contractor for the construction. Production capacities of TITAN-2 Holding are being used in the construction of the new power units, such as Construction Base 1 and Construction Base 2, the concrete batching facility, and shops of TITAN TECHNOLOGY PIPELINE.

Cooperation since the day on which the Leningrad NPP was put into operation

Sosnovy Bor, Leningrad region

Leningrad NPP is the largest power producer in the North-West Region of Russia. The nuclear power facility provides up to 50% of power consumed by St. Petersburg and up to 40% of that consumed by the North-West Federal District. From the date of its commissioning up to the present day, the companies of TITAN-2 Group have been working on all four power units of the plant to ensure the reliable operation of its process equipment and systems and maintain the engineering structures of the buildings and structures of the Leningrad NPP in a proper working order.

The companies of the Group perform a full range of repair, construction, installation and commissioning works and repair reactor, turbine, pump, heat exchanger and electrical equipment. In order to deliver high-quality work, they develop process documents and use state-of-the-art high-tech equipment. The Group’s specialists reconstruct, modernize, maintain and repair over 2,000 units of the plant equipment.

Central Radioactive Waste Conditioning and Long-Term Storage Facility

Sayda Guba, Murmansk Region

The Company’s specialists have erected cable metalwork and have constructed a ventilation system for the facility. The works have been performed by site workers from the Group’s electrical installation companies, i.e. JSC SEM and CJSC TITANVENTEKH. In total, they have constructed 34 forced ventilation power equipment systems and 53 exhaust ventilation systems.

Leningrad Branch of FSUE RosRAO (SIP Radon)

Sosnovy Bor, Leningrad region

The Radioactive Waste Repository of the Leningrad Specialized Integrated Plant “Radon” disposes radioactive waste from the Northwest Region. In order to expand its capabilities and solve the tasks set in the Federal Target Program for Nuclear and Radiation Safety, it has been decided to build a repository for solid radioactive waste.

The Group as the general contractor for the project has performed a full range of works for the construction and installation of repository equipment. The volume of the repository has amounted to 5,000 sq. m. The storage technology requires that processed and detoxified solid radioactive waste be packed into certified non-return protective containers.

PIK Reactor of Konstantinov Petersburg Nuclear Physics Institute

Gatchina, Leningrad region

JSC CONCERN TITAN-2 is the general contractor for the construction and turnkey delivery of the PIK Reactor developed by the Petersburg Nuclear Physics Institute.

The high-flux beam PIK Reactor is the only ongoing project of a modern continuous neutron source in Russia. Its parameters equal or even better (maximum neutron flux and the number of positions on the beams) those of the world’s best research reactors. The PIK Reactor has unique experimental features. The Company’s experts have installed equipment ensuring the safe operation of the reactor and have taken a number of measures for the cooling system and other safety subsystems. The Group’s subsidiaries have performed electrical installation, mechanical assembly and commissioning works. In total, 38 buildings and structures with a total surface area of 65 thousand square meters have been constructed.

Unique contract for the extension of the operating life of Leningrad NPP Power Unit 4

Sosnovy Bor, Leningrad region

Investment project for the extension of the operating life of Leningrad NPP Power Unit 4.

The extension of the service life of operating Leningrad NPP power units has been one of the most labor-intensive and large-scale projects involving the companies of TITAN-2 Group. With its experience in extending the service life of three power units of the Leningrad NPP, in 2008 JSC CONCERN TITAN-2 won the tender for the performance of the full range of works for the modernization, and extension of the service life, of Power Unit 4. As part of a large investment project, TITAN-2 has carried out turnkey works at the plant, including design works, the supply of equipment and commissioning of the facility.

Over 5,000 sets of engineering documentation have been developed within the scope of design and survey works and tens of thousands of pieces of equipment have been supplied for the power unit’s start-up facility. All safety systems of the facility’s power unit and its main and reserve control rooms and standby diesel power plant have been reconstructed, 199 process channels have been replaced, turbines have been rebladed, etc. Power Unit 4 is a second-generation one. It was constructed with due regard to the practice of the construction and operation of the first units and using a new regulatory framework. That is why its modernization has extended its service life for 20 rather than 15 years, i.e. until 2031.

Extending the service life of Leningrad NPP Power Units 1, 2 and 3

Sosnovy Bor, Leningrad region

Leningrad Nuclear Power Plant has been one of the first in the country to undergo multi-level reconstruction which has significantly improved its operating safety and reliability. The operating life of Power Units 1, 2 and 3 has been extended as part of that multi-year campaign through an in-depth safety assessment, the determination of the remaining life of the operating equipment and the modernization of the power units’ safety systems. The companies of the Group have been involved as independent construction and installation companies. Particularly unique never-before-performed works include the modernization of the emergency reactor cooling system (ERCS) by installers within a very short time and the first-time replacement of the reactor’s process channels with a view to restoring the clearance within the TK-Graphite system using a technology exclusively owned by the companies of TITAN-2 Group.

Radioactive Waste Storage and Treatment Facility of the Leningrad NPP

Sosnovy Bor, Leningrad region

The construction of a radioactive waste storage and treatment facility of the Leningrad NPP was commissioned by Rosenergoatom State Concern as part of its efforts to improve the radioactive waste management system through the introduction of new facilities.

In addition to the existing solid radioactive waste repository of the Leningrad NPP, which is designed for the long-term storage of low-, intermediate- and high-level solid radioactive waste (SRW), a special facility has been constructed for the treatment of low- and intermediate-level SRW. This is a high-tech facility designed to make the existing radioactive waste storage system even more reliable and environmentally friendly.

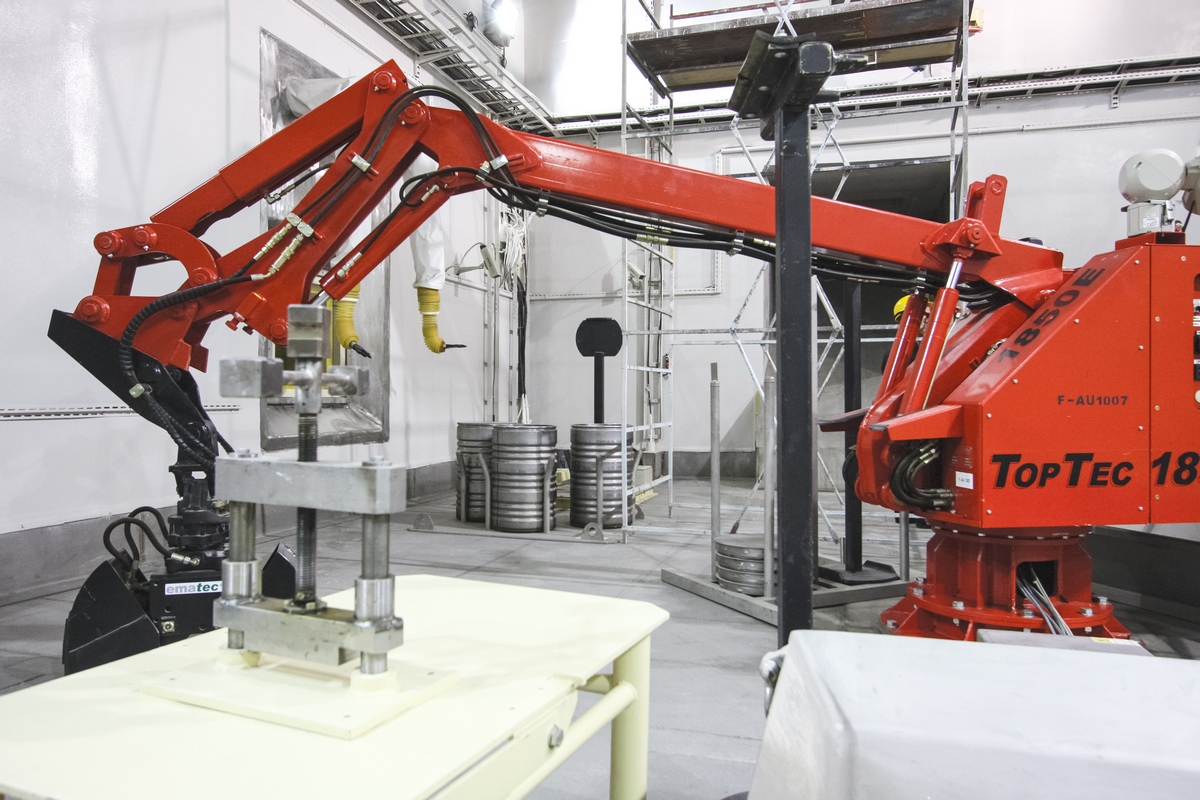

TITAN-2 Group’s specialists have performed a full range of works for the construction, erection, wiring and commissioning of the special facility. The main developer of SRW treatment technologies and engineering documents and the main equipment supplier was Nukem Technologies GmbH (Germany). The unique equipment has been installed by the Group’s experts.

The companies of TITAN-2 have carried out works both in main and auxiliary and utility buildings of the facility and have been involved in the construction of cable tray systems, external power supply, communications and signaling networks and recycling water, heat, steam and air supply systems.

FSUE Aleksandrov Institute of Research and Technology

Sosnovy Bor, Leningrad region

The companies of TITAN-2 Group have been involved in the construction of a single European large-scale complex thermophysical and thermohydraulic test facility (LSF) at the Aleksandrov Institute of Research and Technology for the experimental testing and assessment of the safety of new-generation NPP projects; as well as in the construction of a test facility for the testing and analysis of innovative marine nuclear power plants.

The North-West Research and Production Atomic Energy Center is currently being created at the premises of the Institute. Upon request from Rosatom State Corporation, in the fall of 2010, TITAN-2 Group started modernizing and developing the Institute’s experimental base. Its equipment, technological systems and electrical and computer networks are being modernized in a stepwise manner. Under this project, the companies of the Group are modernizing normal service water supply systems, power equipment, electric lighting and fire-fighting systems and are performing other works.

MAYAK Production Association

Ozersk, Chalyabinsk Region

The Company is modernizing a reactor plant and is constructing a waste cementation facility.